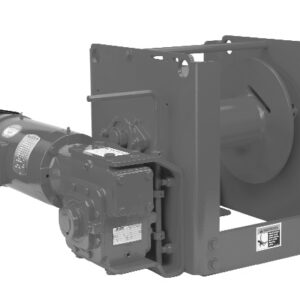

CAPSTAN WINCHES

VC 2000-26 / VC 5000-30 / VC 5000-45 / VC 8000-13 / VC 8000-30 / VC 12000-17 / VC 15000-13 / VC 18000-17 / VC 22000-17

Direct Drive

A direct-drive design increases the efficiency of the capstan winch and eliminates drive chains or bull gears to maximize power output.

Any Angle

The rope can leave the drum at any angle, enabling the operator to stand in the most appropriate, out-of-line-of-sight location. For safety, the load line shall be the bottom wrap on the drum, and the lead line going to the operator will be the top wrap on the drum

Gear Reducers

All Jeamar capstan winches utilize high-efficiency worm, helical, helical-worm or helical-bevel reducers plus high-capacity, anti-friction bearings designed for long life, low noise and higher output torque.

High Starting Loads

High-starting-torque, 3-phase motors are available in all standard voltages at 50 and 60 Hz. These motors are suited to railcar pulling where momentary overloads occur when a railcar is started in motion. Single phase motors at 115/230 volts at 50 or 60 Hz are available as an option on some models.

Load Calculations

For detail on pulling railcars up grades, send for our free railcar pulling brochure.

Controls

Capstans can be supplied with start/stop, foot-operated controls of the “deadman” variety. If the operator’s foot moves off the switch, the capstan will stop. This type of control allows the operator to use two hands on the rope, for optimum control.

Hydraulic and Air-Driven Motors

Capstan winches can be supplied with either hydraulic or air motors.

Explosion Proof

Fully explosion-proof motors and controls are available for applications in hostile or volatile environments.

Torque Limitation

Capstans can be supplied with a variable frequency drive (VFD) package. The VFD controls the amount of current that the motor can draw, limiting the amount of torque that the electric motor can produce.

Description

| Model Number | VC 2000-26 | VC 5000-30 | VC 5000-45 | VC 8000-13 | VC 8000-30 | VC 12000-17 | VC 15000-13 | VC 18000-17 | VC 22000-17 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Working Load Limit Starting | lb | 2000 | 5000 | 5000 | 8000 | 8000 | 12000 | 15000 | 18000 | 22000 | |

| kg | 907 | 2268 | 2268 | 3628 | 3628 | 5442 | 6803 | 8163 | 9977 | ||

| Working Load Limit Running | lb | 1000 | 2,500 | 2500 | 4000 | 4000 | 6000 | 7500 | 9000 | 11000 | |

| kg | 454 | 1134 | 1134 | 1814 | 1814 | 2721 | 3401 | 4082 | 4989 | ||

| Rope Speed | ft/min | 26 | 30 | 45 | 13 | 30 | 17 | 13 | 1 7 | 17 | |

| m/min | 8 | 9 | 14 | 4 | 9 | 5 | 4 | 5 | 5 | ||

| Rope Diameter* (Polypropylene) | in | 5/8 | 1-1/8 | 1-1/8 | 1-1/2 | 1-1/2 | 1-3/4 | 2 | – | – | |

| mm | 16 | 29 | 29 | 38 | 38 | 44 | 50 | – | – | ||

| Rope Diameter* (Spect-Set) | in | 5/8 | 5/8 | 5/8 | 3/4 | 3/4 | 7/8 | 1 | 1-1/4 | 1-1/4 | |

| mm | 16 | 16 | 16 | 20 | 20 | 22 | 25 | 32 | 32 | ||

| Motor | Hp | 1.5 | 3 | 5 | 3 | 5 | 5 | 5 | 7.5 | 7.5 | |

| kW | 1.1 | 2.3 | 3.8 | 2 | 3.8 | 3.8 | 3.8 | 5.7 | 5.7 | ||

| Weight | lb | 202 | 330 | 355 | 452 | 474 | 660 | 1124 | 1162 | 1379 | |

| kg | 92 | 150 | 161 | 205 | 215 | 299 | 510 | 527 | 625 | ||

| Dimensions | A | in | 9.00 | 9.00 | 9.00 | 14.50 | 14.50 | 14.50 | 17.00 | 17.00 | 17.00 |

| mm | 229 | 229 | 229 | 368 | 368 | 368 | 432 | 432 | 432 | ||

| B | in | 5.58 | 6.00 | 6.00 | 6.75 | 8.75 | 8.75 | 10.50 | 10.50 | 12.40 | |

| mm | 142 | 152 | 152 | 222 | 222 | 222 | 267 | 267 | 315 | ||

| C | in | 14.66 | 26.39 | 26.39 | 27.62 | 27.62 | 30.00 | 32.00 | 32.66 | 51.66 | |

| mm | 372 | 670 | 670 | 702 | 702 | 762 | 813 | 830 | 1312 | ||

| D | in | 11.83 | 14.00 | 14.00 | 18.00 | 18.00 | 19.77 | 23.69 | 23.69 | 22.90 | |

| mm | 300 | 356 | 356 | 457 | 457 | 502 | 602 | 602 | 582 | ||

| E | in | 8.95 | 10.05 | 10.05 | 11.81 | 11.81 | 13.75 | 16.09 | 16.09 | 11.88 | |

| mm | 227 | 255 | 255 | 300 | 300 | 349 | 409 | 409 | 302 | ||

| F | in | 5.25 | 11.50 | 11.50 | 11.50 | 11.50 | 11.50 | 11.50 | 11.50 | 11.50 | |

| mm | 133 | 292 | 292 | 292 | 292 | 292 | 292 | 292 | 292 | ||

| G | in | 0.75 | 0.75 | 0.75 | 1.00 | 1.00 | 1.00 | 1.25 | 1.25 | 1.25 | |

| mm | 19 | 19 | 19 | 25 | 25 | 25 | 32 | 32 | 32 | ||

| H | in | 4.00 | 7.00 | 7.00 | 7.00 | 7.00 | 9.00 | 11.00 | 11.00 | 11.00 | |

| mm | 102 | 178 | 178 | 178 | 178 | 229 | 279 | 279 | 279 | ||

| J | in | 0.81 | 0.81 | 0.81 | 1.06 | 1.06 | 1.06 | 1.31 | 1.31 | 1.31 | |

| mm | 21 | 21 | 21 | 27 | 27 | 27 | 33 | 33 | 33 | ||

| K | in | 11.00 | 11.00 | 11.00 | 17.50 | 17.50 | 17.50 | 21.00 | 21.00 | 21.00 | |

| mm | 279 | 279 | 279 | 445 | 445 | 445 | 533 | 533 | 533 | ||

None.

None.