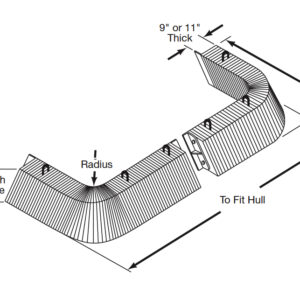

D-GUARD PUSH KNEE FENDER

MODEL 114B – DESIGN SPECIFICATIONS

Features

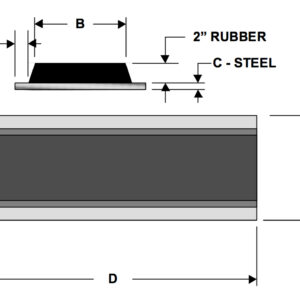

• Nylon-reinforced rubber D-guard sections are compressed onto 1-1/4” steel rods and secured with heavy-duty flatbar or angle

• Weld-tabs are compressed onto steel rods typically at 12” intervals and are welded directly to hull

• Each weld-tab floats and works independent of other weld-tabs, thereby providing quick installation on irregular and damaged hulls

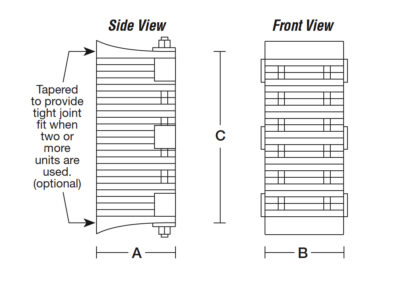

• Rubber is tapered at ends to provide tight joint when two or more units are used (optional)

• Provides up to 500% more rubber protection (10” vs. 2”) compared to molded rubber

• Tough plies of nylon-reinforced rubber virtually eliminate chipping, unlike molded rubber or wood plank bumpers

• Fenders come complete with weld-tabs – no need to incur costs associated with pinning extruded rubber into channel

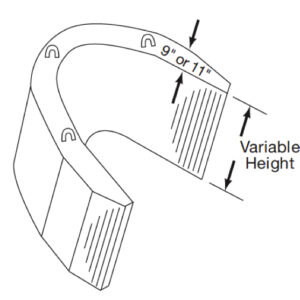

• Mounted vertically on push knees

• Mounted horizontally as side, stern and bow fenders

• Compression tests have demonstrated maximum impact absorption and reflection

• U.S. Coast Guard accepted

• Unaffected by salt water, ozone and oil

• 100% of rubber content is certified to be recycled

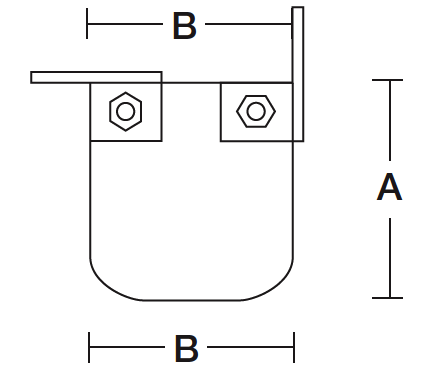

| PART NO. | A | B | C | WT. (Lbs. per Sq. Ft.) |

|---|---|---|---|---|

| SR 114 B 0609 | 6” | 9” |

12” to 480” |

36 |

| SR 114 B 0808 | 8” | 8” | 37 | |

| SR 114 B 0810 | 8” | 10” | 42 | |

| SR 114 B 1010 | 10” | 10” | 46 |

Specify attachment system when placing order.

Description

Attachment Systems

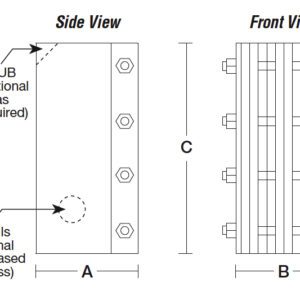

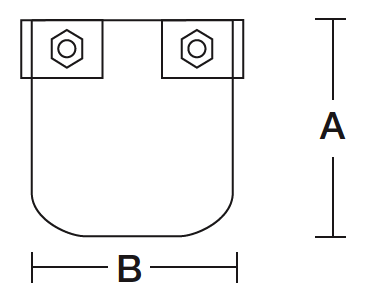

A. FLUSH WELD-TAB

Welded directly to knee or welded into channel

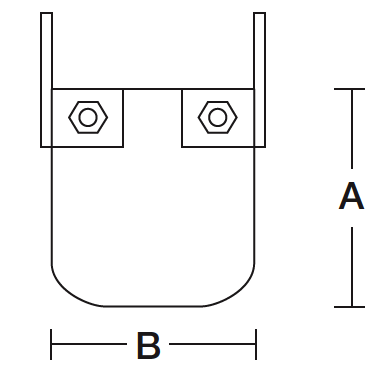

B. EXTENDED WELD-TAB

Welded over existing structure, guardrail or sponson

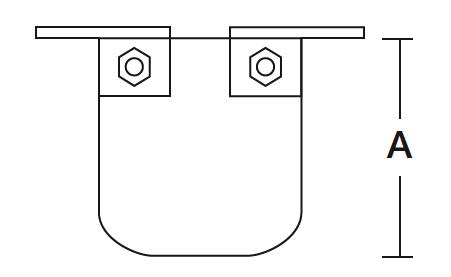

C. BROADMOUNT WELD-TAB

Welded directly to hull

Increased area of weld for added strength

D. COMBINATION

Any combination of weld-tabs is available for custom fit

None.

None.