VERTICAL PUSH KNEE FENDER

MODEL 115 – DESIGN SPECIFICATIONS

Features

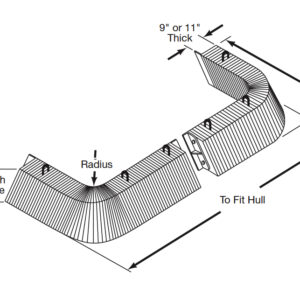

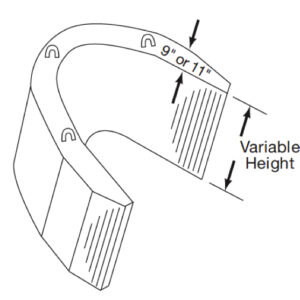

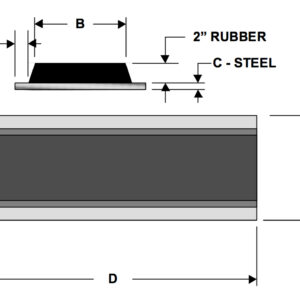

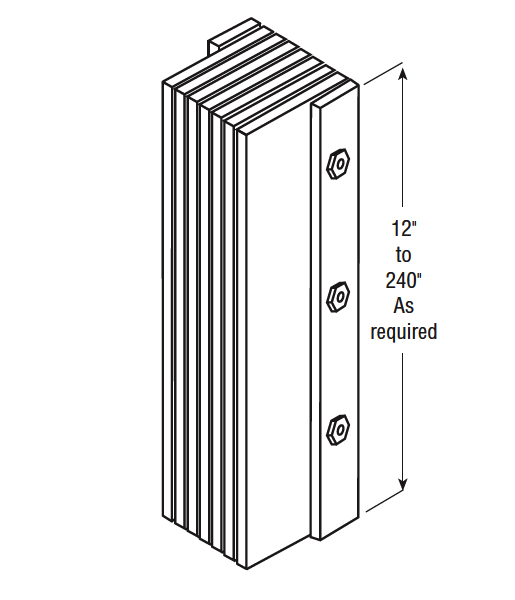

• Nylon-reinforced rubber sections compressed onto 1-1/4” or 1-1/2” steel rods and secured with heavy-duty steel flatbar or angle

• Entire length of fender can be welded directly to push knee structure

• Provides up to 550% more rubber protection (11” vs. 2”) compared to molded rubber

• Tough plies of nylon-reinforced rubber virtually eliminate chipping, unlike molded rubber or wood plank bumpers

• Compression tests have demonstrated maximum impact absorption and reflection

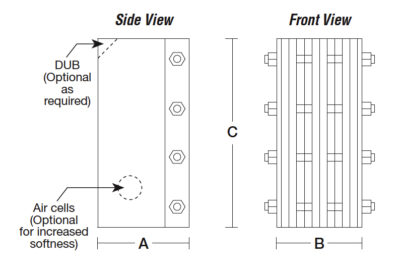

• Air cells can be punched into rubber sections to increase “softness”

• U.S. Coast Guard accepted

• Unaffected by salt water, ozone and oil

• 100% of rubber content is certified to be recycled

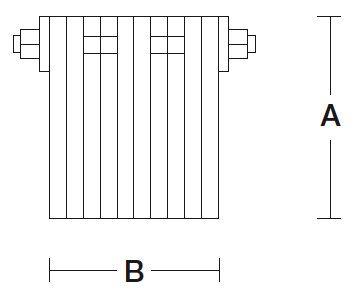

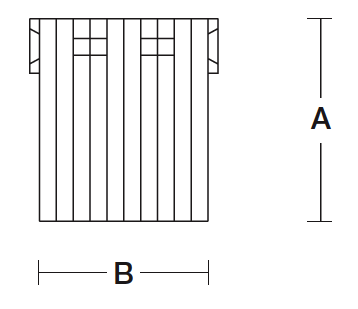

| PART NO. | A | B | C | WT. (Lbs. per Sq. Ft.) |

|---|---|---|---|---|

| SR 115 V | 6” to 11” | 6” to 240” | 12” to 120” | 6” – 43 |

| 7” – 47 | ||||

| 8” – 52 | ||||

| 9” – 56 | ||||

| 10” – 61 | ||||

| 11” – 65 |

Description

Attachment Systems

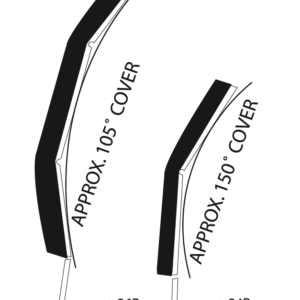

A. STANDARD

Securing flatbar welded directly to knee

B. COUNTERSINK

Same as A except through rods are countersunk and welded into flatbar

Welded or bolted onto existing channel

C. ANGLE

Securing angle welded or bolted directly to knee

D. EXTENDED

Securing flatbar extends over knee structure for welding or bolting

E. WELD-LESS

Countersink style with pre-punched through ways

Attachment bolts pass through I-beam or channel and pre-punched through ways in fender

No welding required

None.

None.