AIR-SEAL STUFFING BOXES

MODELS

1786-IR – WATER-GREASE LUBRICATION, WITH “AIR-SEAL”

1787-IR – GREASE LUBRICATION, WITH “AIR SEAL”

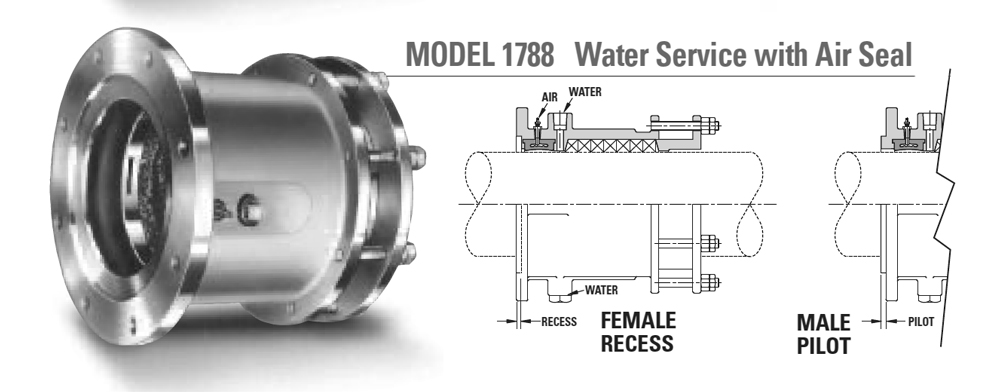

1788-IR – WATER LUBRICATION ONLY, WITH “AIR SEAL”

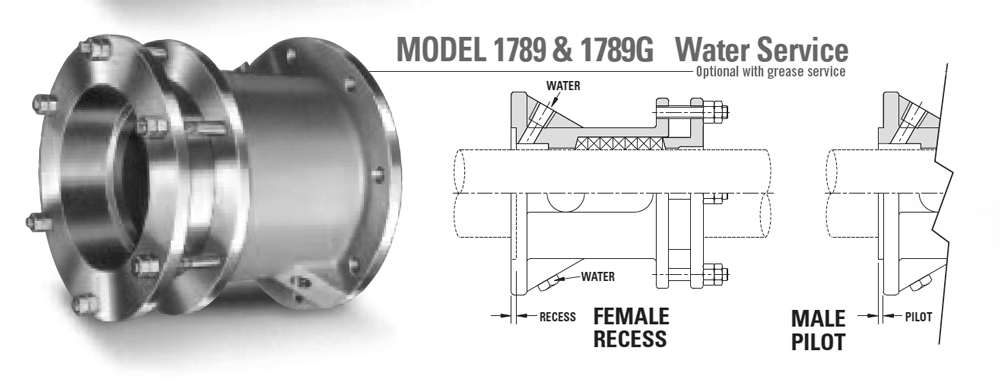

1789 – WATER LUBRICATION

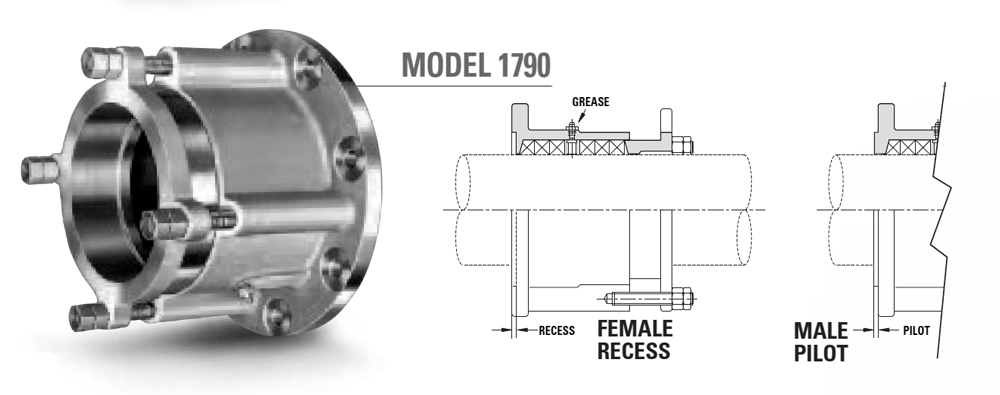

1790 – GREASE LUBRICATED

Description

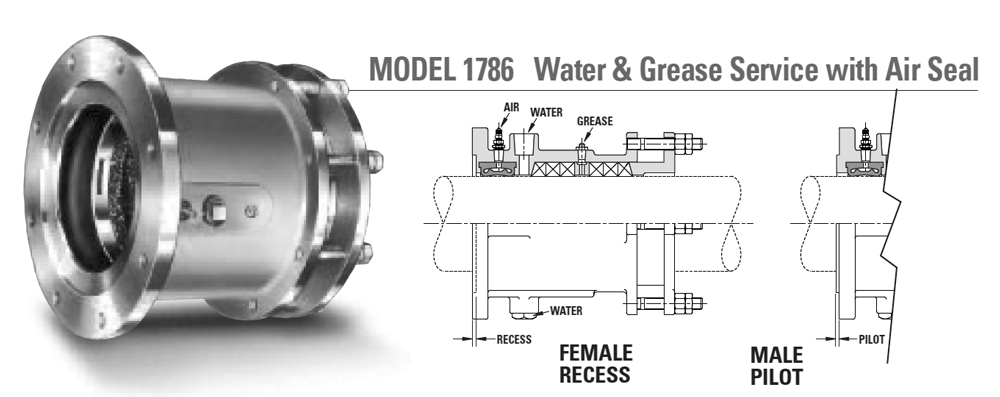

FIG. 1786-IR – WATER-GREASE LUBRICATION, WITH “AIR-SEAL”

For use with water-lubricated stern tube bearings. Fig. 1786-IR is fitted with inflatable “Air-Seal” ring; also inlets for water lubrication to bearings, and “zerk” fitting with lantern-ring for grease lubrication of packing.

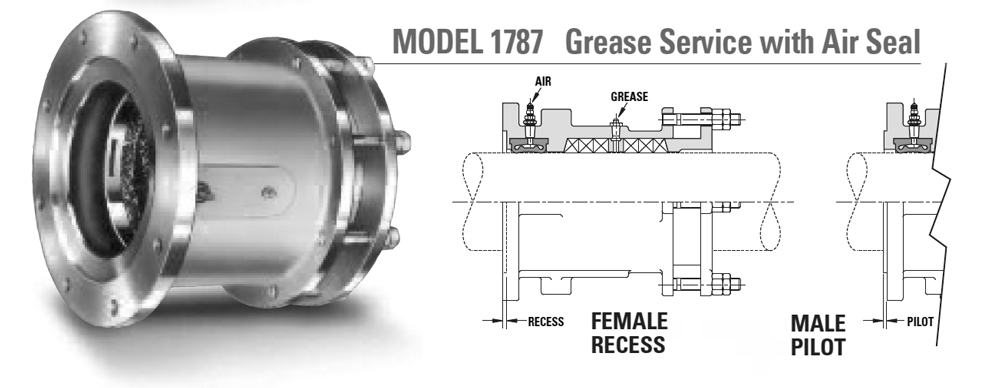

FIG. 1787-IR – GREASE LUBRICATION, WITH “AIR SEAL”

Identical to Fig. 1786-IR, but does not include inlets for water lubrication. Suitable for a short stern-tube where a forward bearing is not used. Includes “zerk” fitting and lantern-ring for grease-lubrication of packing.

FIG. 1788-IR – WATER LUBRICATION ONLY, WITH “AIR SEAL”

Fitted with water inlet for bearing lubrication. Does not include grease fitting or lantern-ring; packing gland accommodates seven rings of packing as opposed to six for grease-lubricated glands. For use with self-lubricated packing.

FIG. 1789 – WATER LUBRICATION

Lower in cost, does not include “Air-Seal” feature nor packing grease-fitting, but is otherwise the equal of the foregoing models. Water inlet delivers water to stern tube bearings.

FIG. 1790 – GREASE LUBRICATED

2-1/2” TO 7-3/4” (63.50 TO 196.85 mm)

For vessels with shafts up to 7-3/4” (196.85 mm) this economical unit offers high efficiency at moderate cost. Equipped with grease-fitting, lantern-ring and space for six rings of packing. Four glandstuds are mounted in ridges cast in barrel, providing high strength for gland compression.

None.

None.