TACHOMETERS AND TACH/HOURMETERS

Series: ATS, ATA, ATHA, ATHS

3000 RPM – 0 to 100,000 Hours

Sensing from Magnetic Sensor Signal or Battery Charging Alternator

• High Visibility Analog Readout

• Air Core Movement

• Easy Calibration

• Through Dial Lighting

• Powered by 12 VDC Battery Converter for 24 to 12 VDC Available

Description

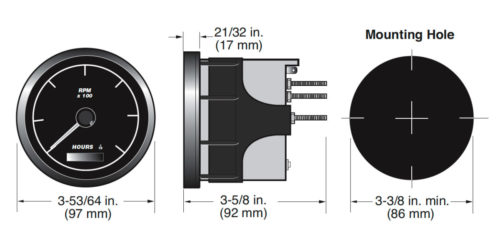

The tachometer is a rugged, transistorized instrument with solid-state circuitry for indication of engine revolutions per minute (RPM). It is equipped with a bracket for mounting into a standard 3-3/8 in. (86 mm.) dash mounting hole. The tachometer’s full 270° sweep of the pointer gives an accurate indication on a large easy–to–read scale. The dial can be illuminated for night reading. The models equipped with tachometer and hourmeter also record the elapsed running time of an engine.

Models for Alternator or Magnetic Sensor

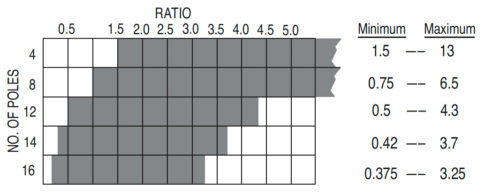

These instruments are designed to function from pulses generated by an alternator with 4, 8, 12, 14 or 16 poles on the rotor, or the pulses can be obtained from the ring gear of an engine by means of an electromagnetic sensor (magnetic pickup). Murphy’s magnetic sensor driven models are designed to function with flywheels having anywhere from 70 to 225 teeth.

All models are for negative ground, positive ground or isolated electrical systems and are protected against reverse polarity hookup. If the instrument is connected reverse polarity, it will not operate until proper connections are made. The tachometer is powered by 12 VDC.

Description

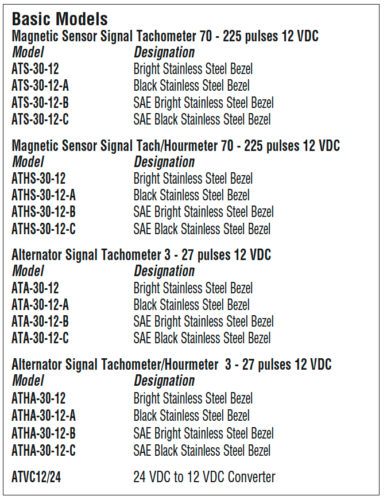

Basic Models

Magnetic Sensor Signal Tachometer 70 – 225 pulses* 12 VDC

Model & Designation

ATS-30-12 Bright Stainless Steel Bezel

ATS-30-12-A Black Stainless Steel Bezel

ATS-30-12-B SAE Bright Stainless Steel Bezel

ATS-30-12-C SAE Black Stainless Steel Bezel

Magnetic Sensor Signal Tach/Hourmeter 70 – 225 pulses* 12 VDC

Model & Designation

ATHS-30-12 Bright Stainless Steel Bezel

ATHS-30-12-A Black Stainless Steel Bezel

ATHS-30-12-B SAE Bright Stainless Steel Bezel

ATHS-30-12-C SAE Black Stainless Steel Bezel

Alternator Signal Tachometer 3 – 27 pulses* 12 VDC

Model & Designation

ATA-30-12 Bright Stainless Steel Bezel

ATA-30-12-A Black Stainless Steel Bezel

ATA-30-12-B SAE Bright Stainless Steel Bezel

ATA-30-12-C SAE Black Stainless Steel Bezel

Alternator Signal Tachometer/Hourmeter 3 – 27 pulses* 12 VDC

Model & Designation

ATHA-30-12 Bright Stainless Steel Bezel

ATHA-30-12-A Black Stainless Steel Bezel

ATHA-30-12-B SAE Bright Stainless Steel Bezel

ATHA-30-12-C SAE Black Stainless Steel Bezel

ATVC12/24 24 to 12 VDC Converter

Specifications

Power Input: 12 VDC (11.5 – 16 V)

RPM Input Signal Voltage: 1.5 Vrms minimum from a magnetic pickup or alternator (minimum 3-pole)

Accuracy: Tachometer: ± 2% full scale Hourmeter: ± 0.01% hours, ± 1 count

Temperature Range: -5°F to 185°F (-20°C to +85°C)

Dial (Face Plate): 270° sweep with white numerals (over black background)

Bezel: 304 Stainless Steel

Scale: 0-3000 RPM

Case Material: Plastic

Hourmeter Range: Measures elapsed time: 100,000 hours in 0.1 increments (tenths)

Shipping Weight: 0.89 lb. (403 g)

Shipping Dimensions: 5-1/2 x 5-1/2 x 5-1/2 in. (140 x 140 x 140 mm.)

Warranty

A one-year limited warranty on materials and workmanship is given with this Murphy product. Details are available on request and are packed with each unit.