MARINE CHOCKING COMPOUNDS

Description

A two-component, 100% solids, high-strength, heat-resistant, pourable epoxy-resin chock designed to replace steel chocks for maintaining permanent alignment of industrial equipment and machinery.

Description

- Thin pour, depths of 1” or less

- High modulus and high compressive strength

- High heat-distortion temperature, 210˚F

- Maximum effective load-bearing area

- Lower thermal conductivity than steel

- Increased free-flow of air under equipment

- Excellent resistance to corrosion and degradation by water, oils, salts, non-oxidizing acids and most solvents

Basic Uses

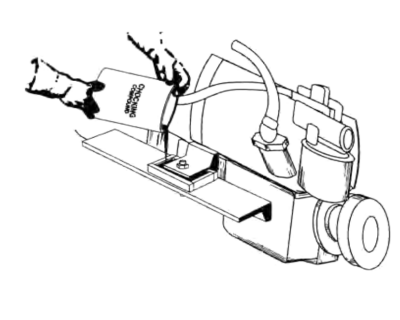

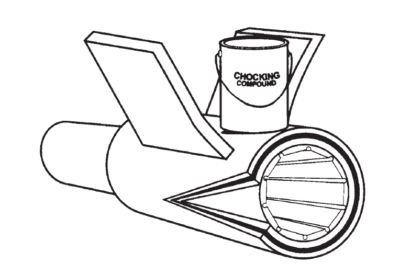

- Marine bearings

- Reciprocating and centrifugal equipment

- Steam and gas turbines

- Pumps and motors

- Crushers, grinding mills, hoists

- Hydraulic presses and other equipment

- Marine engines & transmissions

CHOCKING INSTALLATION MATERIALS

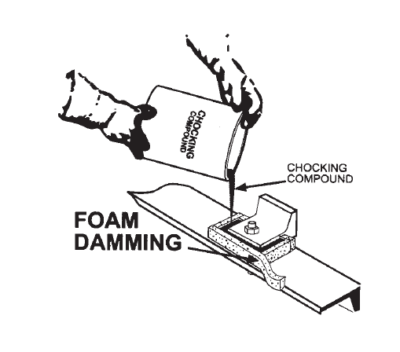

Open-Cell Foam Damming

• Chocks Must Be Retained Within Forms Until Cured

• Forms Must Be Sealed Watertight At Joints

Jiffy Mixers

• Used To Mix Chocking Compounds

• Mix About 3-Minutes At A Slow Speed Of 200-300 Rpm

Release Agent

• To Be Sprayed On Bolts, Foam Damming Or Other Surfaces To Prevent Adhesion To Chock

• 13oz. Size

None.

None.