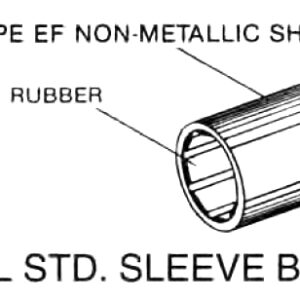

TAILSHAFT SLEEVES

NICKEL-CHROME-BORON HARD-COATED SLEEVES

The Complete Thermal Coating Facility

• NCB Shaft Sleeves

• Shafts

• Pump Components

• Other Castings

Available in: Stainless Steel, U.S. Naval Bronze, Brass Castings

Timco offers complete repair and fabrication of pump components, hardened shaft sleeves and shafts in both the marine and industrial fields. As part of our maintenance cost-savings solution, we offer NCB shaft sleeves, which have been proven to extend both shaft and bearing life in abrasive marine and industrial applications.

Nickel-Chrome-Boron Fused Coatings

Nickel-Chrome-Boron (NCB), properly blended with exacting amounts of copper, molybdenum, iron and carbon, offer a superior material for hard-coating the outside surface of tailshafts and rudder stock liners. NCB offers abrasion- and corrosion-resistance superior to #316 stainless steel and, when fused to carbon steel, will not chip, crack or peel. The

finished, hard-coated surface has a low coefficient-of-friction and hardness in the 60 Rockwell “C” scale range. NCB fuse-coated shafts or shaft sleeves increase shaft life when operating in corrosive/abrasive environments.

Our High Velocity Oxy Fuel (HVOF) System delivers alloys in a fused state with superior bond strength. The advantage of this system is the ability to hard-coat irregular shapes such as pump impellers and pump casings. Again, the advantage of hard-coating pump parts, centrifuge parts and other wear-related components is to reduce wear and extend operating life.

Our complete machine is shop capable of machining parts up to 64” in diameter. Pump components, shafts and shaft sleeves are final-machined to specifications and ground to the specified surface finish. The shop also includes horizontal milling capabilities and complete cylinder grinding, as well as welding fabrication departments.

Description

Extend Bearing & Shaft Life!

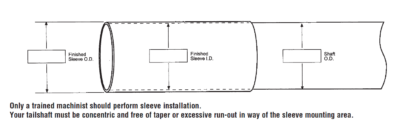

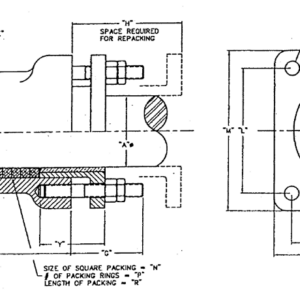

When ordering, specify the following information (use the illustration below, if necessary):

______ Finished Sleeve O.D. (Outside Diameter)

______ Finished Sleeve I.D. (Inside Diameter)

______ Tolerance (if sleeve is to be bore finished)

______ I.D. Rough-Bored (undersized) Sleeve

______ Shaft O.D. (Outside Diameter)

Also specify: No bevel, Bevel one end, Bevel both ends