53 – 57 CAST IRON SERIES

COMPARE THESE FEA TURES

• Non-Clogging vortex impeller

• Float operated, submersible (NEMA 6) 2-pole mechanical switch & variable level long cycle systems available

• UL Listed 3-wire cord plug; 9 ft. standard for automatic, 15 ft. standard for nonautomatic

• Corrosion resistant powder coated epoxy finish

• No sheet metal parts to rust or corrode

• Stainless steel screws, switch arm, guard and handle

• No screens to clog

• Watertight neoprene “[]” ring between motor and pump housing

• Solid buoyant polypropylene float

• Motor – 60 Hz, 1550 RPM, oil-filled, hermetically sealed, automatic reset thermal overload protected

• Upper and lower sleeve bearings running in bath of oil

• Entire unit pressure tested after assembly

• Carbon and ceramic shaft seal

• Maximum temperature for effluent or dewatering—130°F (54°C)

• Passes 1/2″ inch spherical solids

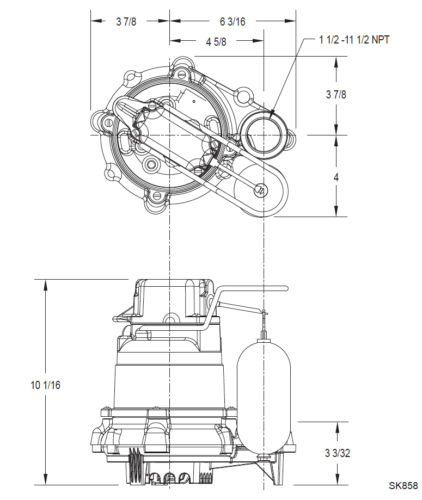

• 1-1/2″ NPT Discharge.

• On point—7-3/4

• Off point—3″

• Major width—10 3/32″

• Height—10 1/16″

ALL MODELS ARE COMPLETELY SUBMERSIBLE

HERMETICALLY SEALED

Watertight – dust tight. Permanently oiled bearings.

VARIABLE LEVEL CONTROL SYSTEMS AVAILABLE

Note: The sizing of effl uent systems normally requires variable level float(s) controls and properly sized basins to achieve required pumping cycles or dosing timers with nonautomatic pumps.

Description

SPECIAL MODEL FEATURES

Model 53

• Cast iron switch case, motor & pump housing

• Engineered thermoplastic base

• Engineered, glass-filled, plastic impeller with metal insert

• Stainless steel guard & handle

• Bearing – lower & upper oil fed cast iron

Model 57

• All cast iron construction

• Stainless steel guard & handle

• Bearing – lower & upper oil fed cast iron

• Cast iron impeller

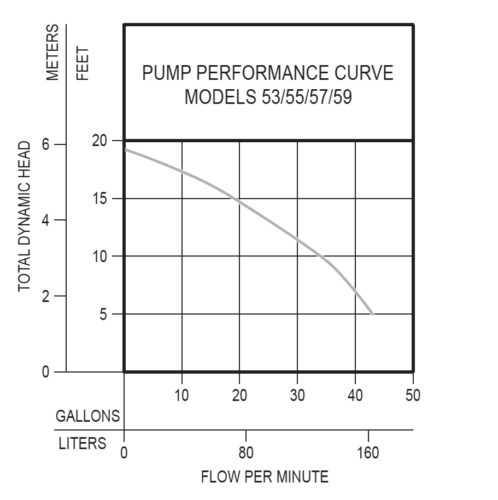

TOTAL DYNAMIC HEAD/FLOW PER MINUTE EFFLUENT AND DEWATERING

MODEL | 53/55/57/59 | ||

Feet | Meters | Gal. | Liters |

5 | 1.5 | 43 | 163 |

10 | 3.0 | 34 | 129 |

15 | 4.6 | 19 | 72 |

Shut-off Head: | 19.25 ft.(5.9m) | ||

CONSULT FACTORY FOR SPECIAL APPLICATIONS

• Variable level float switches available

• Variable level long cycle systems available

• Available with special cord lengths of 15′, 25′, 35′, (50′ 230V only)

• Alarm systems available

• Duplex systems available

SELECTION GUIDE

1. Integral float operated mechanical switch, no external control required.

2. Single piggyback variable level float switch or double piggy back variable level float switch. Refer to FM0477.

3. Mechanical alternator “M-Pak” 10-0072 or 10-0075.

4. See FM0712 for correct model of Electrical Alternator.

5. Variable level control switch 10-0225 used as a control activator, with Electrical Alternator (3) or (4) float system.

Single Seal | Control Selection | Listings | ||||||

|---|---|---|---|---|---|---|---|---|

Model | Volts | Phase | Mode | Amps | Simplex | Duplex | CSA | UL |

M53/55 & M57/59 | 115 | 1 | Auto | 9.7 | 1 | —– | Y | Y |

N53/55 & N57/59 | 115 | 1 | Non | 9.7 | 2 | 3 or 4 & 5 | Y | Y |

* BN53 | 115 | 1 | Auto | 9.7 | * | —– | Y | Y |

* BN57 | 115 | 1 | Auto | 9.7 | * | —– | N | Y |

* BE53/57 | 230 | 1 | Auto | 4.8 | * | —– | Y | Y |

D53/55 & D57/59 | 230 | 1 | Auto | 4.8 | 1 | —– | Y | Y |

E53/55 & E57/59 | 230 | 1 | Non | 4.8 | 2 | 3 or 4 & 5 | Y | Y |

* Single piggyback switch included.

CAUTION

All installation of controls, protection devices and wiring should be done by a qualified licensed electrician. All electrical and safety codes should be followed including the most recent National Electrical Code (NEC) and the Occupational Safety and Health Act (OSHA).

For information on additional Zoeller products refer to catalog on Piggyback Variable Level Float Switches, FM0477; Electrical Alternator, FM0486; Mechanical Al ter na tor, FM0495; Sump/Sewage Basins, FM0487; and Single Phase Simplex Pump Control/Alarm Systems, FM0732.

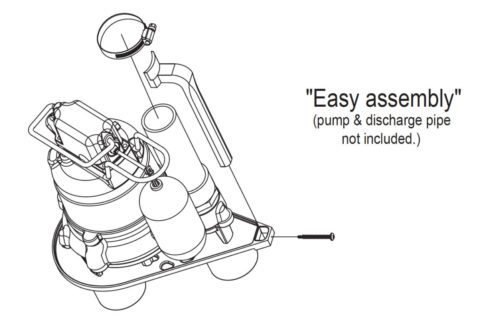

OPTIONAL PUMP STAND P/N 10-2421

• Reduces potential clogging by debris

• Replaces rocks or bricks under the pump

• Made of durable, noncorrosive ABS

• Raises pump 2″ off bottom of basin

• Provides the ability to raise intake by adding sections of 1ó” or 2″ PVC piping

• Attaches securely to pump

• Accommodates sump, dewatering and effl uent applications

NOTE: Make sure fl oat is free from obstruction.