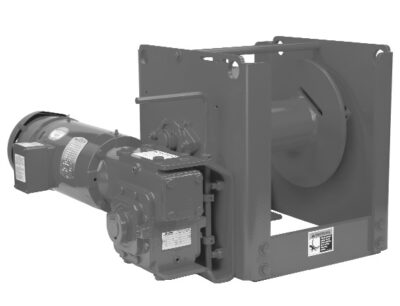

WORM / SPUR GEAR POWER WINCHES

4WS1M6 / 4WS3M10 / 4WS6M12

Up to 6000 lb. capacity

- Modular Design allows us to make-to-order each winch to meet your exact needs.

- Standard Features include TEFC brake motors, enclosed machine cut gearing and flange style ball bearings.

- Custom Modifications available include grooved drums, special drum lengths and diameters, limit switches, roller pressure bars, and special finishes. Pneumatic, hydraulic and alternate motor voltages are also available.

- Two-year Limited Warranty

Description

Series 4WS Electric – Configurations and Performance Characteristics

| MODEL NUMBER EXTENSIONS | LOAD RATING (LB.) | LINE SPEED (FPM) | DRUM CAPACITY (FT)1 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MODEL NUMBER | LOAD RATING | LINE SPEED | MOTOR CODES | CLUTCH OPTION | MOTOR HP | 1ST LAYER | MID DRUM | FULL DRUM | WIRE ROPE DIA. (IN) | 1ST LAYER | FULL DRUM | 1ST LAYER | MID DRUM | FULL DRUM | APPROX. SHIP WT. (LB.)2 |

|

4WS1M6 |

800 |

15 |

A, B, D, E, F |

C |

.5 |

800 |

550 |

420 |

3/16 |

17 |

33 |

21 |

110 |

260 |

155 |

|

4WS1M6 |

800 |

30 |

A, B, D, E, F |

C |

.75 |

800 |

550 |

420 |

3/16 |

29 |

55 |

21 |

110 |

260 |

165 |

|

4WS1M6 |

800 |

40 |

A, B, D, E, F |

C |

1 |

800 |

550 |

420 |

3/16 |

43 |

82 |

21 |

110 |

260 |

175 |

|

4WS1M6 |

1100 |

20 |

A, B, D, E, F |

C |

.75 |

1100 |

800 |

600 |

1/4 |

18 |

32 |

16 |

62 |

140 |

165 |

|

4WS1M6 |

1100 |

30 |

A, B, D, E, F |

C |

1 |

1100 |

800 |

600 |

1/4 |

30 |

54 |

16 |

62 |

140 |

175 |

|

4WS1M6 |

1100 |

40 |

D, E, F |

C |

1.5 |

1100 |

800 |

600 |

1/4 |

44 |

81 |

16 |

62 |

140 |

170 |

|

4WS1M6 |

1500 |

20 |

A, B, D, E, F |

C |

1 |

1500 |

1000 |

800 |

1/4 |

18 |

32 |

16 |

62 |

140 |

175 |

|

4WS1M6 |

1500 |

30 |

D, E, F |

C |

1.5 |

1500 |

1100 |

800 |

1/4 |

30 |

54 |

16 |

62 |

140 |

170 |

|

4WS1M6 |

1500 |

40 |

B, D, E, F |

C |

2 |

1500 |

1100 |

800 |

1/4 |

44 |

81 |

16 |

62 |

140 |

180 |

|

clutch option for 4WS1M6 (for horizontal pulling only) |

add: | 5 | 770 | 770 | |||||||||||

|

4WS3M10 |

2000 |

15 |

A, B, D, E, F |

C |

1 |

2000 |

1300 |

1000 |

5/16 |

14 |

29 |

34 |

220 |

500 |

310 |

|

4WS3M10 |

2000 |

20 |

D, E, F |

C |

1.5 |

2200 |

1400 |

1000 |

5/16 |

18 |

39 |

34 |

220 |

500 |

305 |

|

4WS3M10 |

2500 |

20 |

B, D, E, F |

C |

2 |

2500 |

1600 |

1200 |

3/8 |

22 |

46 |

27 |

160 |

360 |

320 |

|

4WS3M10 |

3000 |

15 |

D, E, F |

C |

1.5 |

3000 |

2000 |

1500 |

3/8 |

14 |

29 |

27 |

160 |

360 |

305 |

|

4WS3M10 |

3000 |

20 |

B, D, E, F |

C |

2 |

3000 |

2000 |

1500 |

3/8 |

19 |

39 |

27 |

160 |

360 |

320 |

|

4WS3M10 |

3500 |

7 |

A, B, D, E, F |

C |

1 |

3500 |

2300 |

1700 |

7/16 |

8 |

15 |

23 |

120 |

270 |

330 |

|

4WS3M10 |

3500 |

15 |

B, D, E, F |

C |

2 |

3700 |

2500 |

1800 |

7/16 |

14 |

29 |

23 |

120 |

270 |

320 |

|

4WS3M10 |

3500 |

20 |

D, E, F |

C |

3 |

3700 |

2500 |

1800 |

7/16 |

23 |

46 |

23 |

120 |

270 |

330 |

| clutch option for 4WS3M10 (for horizontal pulling only) | add: | 8 | 790 | ||||||||||||

|

4WS6M12 |

3000 |

10 |

D, E, F |

C |

1.5 |

3400 |

2200 |

1600 |

3/8 |

12 |

25 |

40 |

300 |

660 |

515 |

|

4WS6M12 |

3000 |

20 |

B, D, E, F |

C |

2 |

3100 |

2000 |

1500 |

3/8 |

20 |

42 |

40 |

300 |

660 |

530 |

|

4WS6M12 |

4000 |

10 |

B, D, E, F |

C |

2 |

4500 |

2900 |

2100 |

7/16 |

12 |

25 |

34 |

220 |

500 |

530 |

|

4WS6M12 |

4000 |

20 |

D, E, F |

C |

3 |

4000 |

2500 |

1900 |

7/16 |

24 |

50 |

34 |

220 |

500 |

540 |

|

4WS6M12 |

6000 |

4 |

A, B, D, E, F |

C |

1 |

6200 |

4000 |

3000 |

1/2 |

4 |

8 |

30 |

170 |

390 |

535 |

|

4WS6M12 |

6000 |

10 |

D, E, F |

C |

3 |

6400 |

4200 |

3100 |

9/16 |

12 |

25 |

26 |

140 |

310 |

540 |

|

4WS6M12 |

6000 |

20 |

D, E, F |

C |

5 |

6400 |

4200 |

3100 |

9/16 |

24 |

50 |

26 |

140 |

310 |

585 |

| clutch option for 4WS6M12 (for horizontal pulling only) | add: | 12 | 980 | ||||||||||||

| MOTOR CODES | ||

|---|---|---|

| A | 115 volt | 1 phase |

| B | 230 volt | 1 phase |

| D | 230 volt | 3 phase |

| E | 460 volt | 3 phase |

| F | All other voltages – please contact factory. | |

Electric Drum Control Switches – Order Separately

| MODEL | DESCRIPTION | 115/1/605 | 230/1/60 | 230/3/60 | 460/3/60 |

|---|---|---|---|---|---|

| EL1CS | NEMA 1 | to 1.5 hp | to 2 hp | to 3 hp | to 3 hp |

| EL2CS | NEMA 1 | to 1.5 hp | to 3 hp | to 5 hp | to 7.5 hp |

| EL1CSW | NEMA 4 – watertight | to 1.5 hp | to 2 hp | to 3 hp | to 3 hp |

| EL2CSW | NEMA 4 – watertight | — | to 3 hp | to 5 hp | to 7.5 hp |

| EL1PD | 6 ft pendant control | to 1 hp | — | — | — |

1 Actual drum capacities 25-30% less, due to nonuniform winding. Wire rope tension will also affect drum capacity.

2 Weight may vary with motor.

3 Please contact Timco for firm fixed price and delivery.

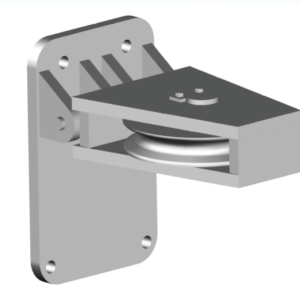

4 Recommended minimum distance between drum and lead sheave for smooth drum.

5 Controls for 115V single phase motors up to 1 hp, include an 8 ft power cord with grounded plug.

6 Please contact Timco for firm fixed price and delivery.

Series 4WS – Winch Dimensions (in)

| MODEL EXTENSION | A | B | C | D | E | H | J | K | M | N | P | R | S (HOLE DIA.) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4WS1M6-800-15 | 21.00 | 21.62 | 3.00 | 6.75 | 2.25 | 11.75 | 1.75 | 6.00 | 9.75 | 1.25 | 8.50 | 11.00 | 0.44 |

| 4WS1M6-800-30 | 21.00 | 22.38 | 3.00 | 6.75 | 2.25 | 11.75 | 1.75 | 6.00 | 9.75 | 1.25 | 8.50 | 11.00 | 0.44 |

| 4WS1M6-800-40 | 21.75 | 23.38 | 3.00 | 6.75 | 2.25 | 11.75 | 1.75 | 6.00 | 9.75 | 1.25 | 8.50 | 11.00 | 0.44 |

| 4WS1M6-1100-20 | 21.00 | 22.38 | 3.00 | 6.75 | 2.25 | 11.75 | 1.75 | 6.00 | 9.75 | 1.25 | 8.50 | 11.00 | 0.44 |

| 4WS1M6-1100-30 | 21.75 | 23.38 | 3.00 | 6.75 | 2.25 | 11.75 | 1.75 | 6.00 | 9.75 | 1.25 | 8.50 | 11.00 | 0.44 |

| 4WS1M6-1100-40 | 21.75 | 22.38 | 3.00 | 6.75 | 2.25 | 11.75 | 1.75 | 6.00 | 9.75 | 1.25 | 8.50 | 11.00 | 0.44 |

| 4WS1M6-1500-20 | 21.75 | 23.38 | 3.00 | 6.75 | 2.25 | 11.75 | 1.75 | 6.00 | 9.75 | 1.25 | 8.50 | 11.00 | 0.44 |

| 4WS1M6-1500-30 | 21.75 | 22.38 | 3.00 | 6.75 | 2.25 | 11.75 | 1.75 | 6.00 | 9.75 | 1.25 | 8.50 | 11.00 | 0.44 |

| 4WS1M6-1500-40 | 21.75 | 25.00 | 3.00 | 6.75 | 2.25 | 11.75 | 1.75 | 6.00 | 9.75 | 1.25 | 8.50 | 11.00 | 0.44 |

| 4WS3M10-2000-15 | 27.75 | 26.75 | 5.00 | 10.12 | 2.38 | 17.50 | 2.38 | 10.00 | 15.00 | 1.88 | 12.75 | 16.50 | 0.59 |

| 4WS3M10-2000-20 | 27.75 | 25.75 | 5.00 | 10.12 | 2.38 | 17.50 | 2.38 | 10.00 | 15.00 | 1.88 | 12.75 | 16.50 | 0.59 |

| 4WS3M10-2500-20 | 27.75 | 28.25 | 5.00 | 10.12 | 2.38 | 17.50 | 2.38 | 10.00 | 15.00 | 1.88 | 12.75 | 16.50 | 0.59 |

| 4WS3M10-3000-15 | 27.75 | 25.75 | 5.00 | 10.12 | 2.38 | 17.50 | 2.38 | 10.00 | 15.00 | 1.88 | 12.75 | 16.50 | 0.59 |

| 4WS3M10-3000-20 | 27.75 | 28.25 | 5.00 | 10.12 | 2.38 | 17.50 | 2.38 | 10.00 | 15.00 | 1.88 | 12.75 | 16.50 | 0.59 |

| 4WS3M10-3500-7 | 27.75 | 32.00 | 5.00 | 10.12 | 2.38 | 17.50 | 2.38 | 10.00 | 15.00 | 1.88 | 12.75 | 16.50 | 0.59 |

| 4WS3M10-3500-15 | 27.75 | 28.25 | 5.00 | 10.12 | 2.38 | 17.50 | 2.38 | 10.00 | 15.00 | 1.88 | 12.75 | 16.50 | 0.59 |

| 4WS3M10-3500-20 | 28.81 | 33.00 | 5.00 | 10.12 | 2.38 | 17.50 | 2.38 | 10.00 | 15.00 | 1.88 | 12.75 | 16.50 | 0.59 |

| 4WS6M12-3000-10 | 33.00 | 26.75 | 5.62 | 12.88 | 2.50 | 22.50 | 3.25 | 12.00 | 19.00 | 1.88 | 18.25 | 22.00 | 0.88 |

| 4WS6M12-3000-20 | 33.00 | 29.50 | 5.62 | 12.88 | 2.50 | 22.50 | 3.25 | 12.00 | 19.00 | 1.88 | 18.25 | 22.00 | 0.88 |

| 4WS6M12-4000-10 | 33.00 | 29.50 | 5.62 | 12.88 | 2.50 | 22.50 | 3.25 | 12.00 | 19.00 | 1.88 | 18.25 | 22.00 | 0.88 |

| 4WS6M12-4000-20 | 34.00 | 29.25 | 5.62 | 12.88 | 2.50 | 22.50 | 3.25 | 12.00 | 19.00 | 1.88 | 18.25 | 22.00 | 0.88 |

| 4WS6M12-6000-4 | 33.00 | 27.75 | 5.62 | 12.88 | 2.50 | 22.50 | 3.25 | 12.00 | 19.00 | 1.88 | 18.25 | 22.00 | 0.88 |

| 4WS6M12-6000-10 | 34.00 | 29.25 | 5.62 | 12.88 | 2.50 | 22.50 | 3.25 | 12.00 | 19.00 | 1.88 | 18.25 | 22.00 | 0.88 |

| 4WS6M12-6000-20 | 34.00 | 31.00 | 5.62 | 12.88 | 2.50 | 22.50 | 3.25 | 12.00 | 19.00 | 1.88 | 18.25 | 22.00 | 0.88 |

Series 4WS – Drum Dimensions

| MODEL EXTENSION | DRUM DIAMETER | FLANGE DIAMETER | DRUM WIDTH | FLEET ANGLE DISTANCE4 |

|---|---|---|---|---|

| 4WS1M6 | 2.88 in | 7.00 in | 6.00 in | 10ft |

| 4WS3M10 | 4.50 in | 11.50 in | 10.00 in | 16ft |

| 4WS6M12 | 5.50 in | 14.00 in | 12.00 in | 20ft |

Dimensions are for reference only and subject to change without notice.

NOTE:

Custom controls are available including wireless remote control, variable speed control, electronic overload, and enclosures for special environments.

Important:

It is the owner’s or operator’s responsibility to determine the suitability of the equipment to its intended use. Study all applicable codes, manuals, and regulations. Be sure to read the Owner’s Manual supplied with the equipment before operating it.

None.