SELF-PRIMING CENTRIFUGAL PUMPS

• 300 Series Investment Cast Stainless Steel Construction with Viton® Seals; Maximum Temperature 200º F

• Cast Iron Construction with Buna-N Seals; Maximum Temperature 180º F

• Optional Silicon Carbide Seals Available

• 1-1/2″ and 2″ NPT Port Sizes

• Self-Priming up to 20 Ft.

• Maximum Working Pressure 75 PSI

• Maximum Flow 150 GPM

• Maximum Head 102 Ft. (44 PSI)

• Dual Volute Design

• Self-cleaning, Clog Resistant Impeller

• Built In Check Valve

• Available with Open Drip Proof (ODP) or Totally Enclosed Fan Cooled (TEFC) Motors

• 1/2 to 3 HP 56J Single and Three Phase, 3450 RPM Motors

This line of AMT Self-priming Centrifugal pumps is designed for Industrial and Commercial applications requiring high volume liquid transfer, waste water drainage and processing. These pumps feature self-cleaning clog resistant impeller capable of handling up to 3/8″ diameter semi-solids. Built in flapper/check valves enable consistent self-priming to 20 ft. Dual volute design reduces radial load on motor. Stainless Steel models are especially effective in applications where rust and/or corrosion can develop in systems and also are highly resistant to erosion and chemicals. Cast Iron models offer durability, high quality and value that continue to set the standard in the industry.

AMT Centrifugal pumps are reliable, cost effective and low maintenance. Many are readily available “Off-the-Shelf” for fast 24 hour shipment. For use with nonflammable liquids compatible with pump component materials.

Viton® is a registered trademark of E.I. DuPont

Description

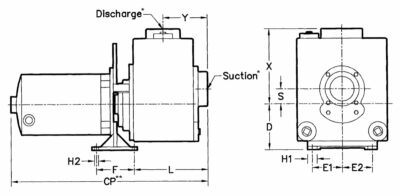

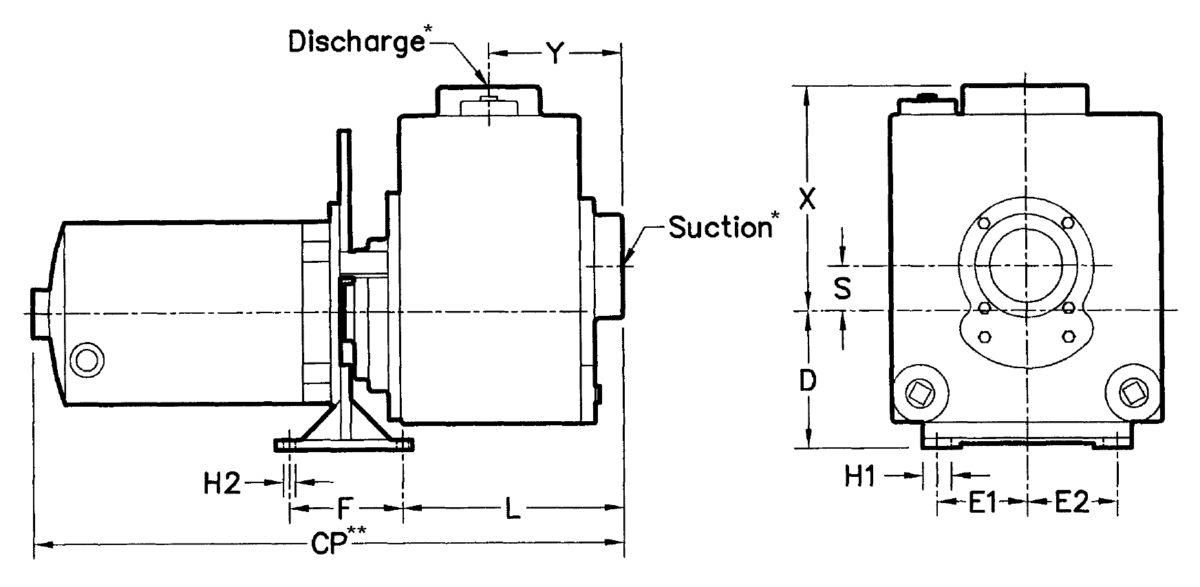

Pump Dimensional & Specification Chart

|

Cast Iron Models |

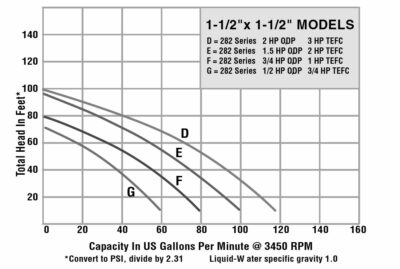

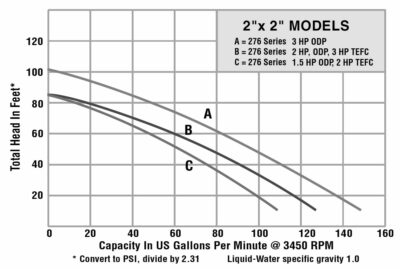

Curve |

Stainless Models |

HP |

PH |

ENC |

Voltage @ 60 Hz+ |

Full Load Amps |

SUC* |

DIS* |

CP** |

D |

E1 |

E2 |

F |

H1 |

H2 |

L |

S |

X |

Y |

Cast Iron Ship Wt |

Stainless Ship Wt |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

2827-95 |

G |

2827-98 |

1/2 |

1 |

ODP |

115/230 |

10/5 |

1-1/2″ |

1-1/2″ |

16.9 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

47 Lbs. |

50 Lbs. |

|

282J-95 |

G |

282J-98 |

1/2 |

3 |

ODP |

230/460 |

4/2 |

1-1/2″ |

1-1/2″ |

17.4 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

51 Lbs. |

53 Lbs. |

|

2825-95 |

F |

2825-98 |

3/4 |

1 |

ODP |

115/230 |

13/7 |

1-1/2″ |

1-1/2″ |

17.6 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

50 Lbs. |

53 Lbs. |

|

2826-95 |

F |

2826-98 |

3/4 |

3 |

ODP |

230/460 |

4/2 |

1-1/2″ |

1-1/2″ |

17.8 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

50 Lbs. |

53 Lbs. |

|

282D-95 |

G |

282D-98 |

3/4 |

1 |

TEFC |

115/230 |

9/5 |

1-1/2″ |

1-1/2″ |

19.0 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

52 Lbs. |

55 Lbs. |

|

282F-95 |

G |

282F-98 |

3/4 |

3 |

TEFC |

230/460 |

3/2 |

1-1/2″ |

1-1/2″ |

18.4 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

49 Lbs. |

52 Lbs. |

|

282C-95 |

F |

282C-98 |

1 |

1 |

TEFC |

115/230 |

12/6 |

1-1/2″ |

1-1/2″ |

19.4 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

55 Lbs. |

58 Lbs. |

|

282K-95 |

F |

282K-98 |

1 |

3 |

TEFC |

230/460 |

4/2 |

1-1/2″ |

1-1/2″ |

19.0 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

51 Lbs. |

54 Lbs. |

|

2821-95 |

E |

2821-98 |

1-1/2 |

1 |

ODP |

115/230 |

22/11 |

1-1/2″ |

1-1/2″ |

16.8 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

62 Lbs. |

65 Lbs. |

|

2822-95 |

E |

2822-98 |

1-1/2 |

3 |

ODP |

230/460 |

7/4 |

1-1/2″ |

1-1/2″ |

16.6 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

58 Lbs. |

61 Lbs. |

|

2828-95 |

D |

2828-98 |

2 |

1 |

ODP |

115/230 |

28/14 |

1-1/2″ |

1-1/2″ |

17.6 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

69 Lbs. |

72 Lbs. |

|

282L-95 |

D |

282L-98 |

2 |

3 |

ODP |

230/460 |

7/4 |

1-1/2″ |

1-1/2″ |

17.7 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

68 Lbs. |

71 Lbs. |

|

282A-95 |

E |

282A-98 |

2 |

1 |

TEFC |

115/230 |

22/11 |

1-1/2″ |

1-1/2″ |

19.2 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

74 Lbs. |

77 Lbs. |

|

282B-95 |

E |

282B-98 |

2 |

3 |

TEFC |

230/460 |

6/3 |

1-1/2″ |

1-1/2″ |

18.0 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

69 Lbs. |

71 Lbs. |

|

282E-95 |

D |

282E-98 |

3 |

1 |

TEFC |

230 |

16 |

1-1/2″ |

1-1/2″ |

20.0 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

80 Lbs. |

83 Lbs. |

|

282M-95 |

D |

282M-98 |

3 |

3 |

TEFC |

230/460 |

8/4 |

1-1/2″ |

1-1/2″ |

20.8 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

5.4 |

0.9 |

5.1 |

3.5 |

80 Lbs. |

83 Lbs. |

|

2762-95 |

C |

2762-98 |

1-1/2 |

1 |

ODP |

115/230 |

17/9 |

2″ |

2″ |

18.4 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

6.7 |

1.2 |

6.7 |

4.4 |

68 Lbs. |

72 Lbs. |

|

2764-95 |

C |

2764-98 |

1-1/2 |

3 |

ODP |

230/460 |

7/4 |

2″ |

2″ |

18.6 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

6.7 |

1.2 |

6.7 |

4.4 |

69 Lbs. |

73 Lbs. |

|

2761-95 |

B |

2761-98 |

2 |

1 |

ODP |

115/230 |

28/14 |

2″ |

2″ |

19.1 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

6.7 |

1.2 |

6.7 |

4.4 |

74 Lbs. |

78 Lbs. |

|

276B-95 |

C |

276B-98 |

2 |

1 |

TEFC |

115/230 |

22/11 |

2″ |

2″ |

20.7 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

6.7 |

1.2 |

6.7 |

4.4 |

79 Lbs. |

83 Lbs. |

|

2763-95 |

B |

2763-98 |

2 |

3 |

ODP |

230/460 |

7/4 |

2″ |

2″ |

19.1 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

6.7 |

1.2 |

6.7 |

4.4 |

67 Lbs. |

71 Lbs. |

|

276D-95 |

C |

276D-98 |

2 |

3 |

TEFC |

230/460 |

6/3 |

2″ |

2″ |

19.4 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

6.7 |

1.2 |

6.7 |

4.4 |

68 Lbs. |

72 Lbs. |

|

2767-95 |

A |

2767-98 |

3 |

1 |

ODP |

230 |

18 |

2″ |

2″ |

20.2 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

6.7 |

1.2 |

6.7 |

4.4 |

76 Lbs. |

79 Lbs. |

|

276A-95 |

B |

276A-98 |

3 |

1 |

TEFC |

230 |

16 |

2″ |

2″ |

21.4 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

6.7 |

1.2 |

6.7 |

4.4 |

79 Lbs. |

83 Lbs. |

|

2766-95 |

A |

2766-98 |

3 |

3 |

ODP |

230/460 |

9/5 |

2″ |

2″ |

19.9 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

6.7 |

1.2 |

6.7 |

4.4 |

74 Lbs. |

78 Lbs. |

|

276C-95 |

B |

276C-98 |

3 |

3 |

TEFC |

230/460 |

8/4 |

2″ |

2″ |

20.9 |

4.5 |

2.2 |

2.2 |

3.0 |

0.5 |

0.7 |

6.7 |

1.2 |

6.7 |

4.4 |

76 Lbs. |

80 Lbs. |

(*) Standard NPT (female) pipe thread.

(**) This dimension may vary due to motor manufacturer’s specifications.

(+) 3-Phase motors can also operate on 50 Hz. (This will change Full Load Amps, Service Factor, RPM and Priming Capabilities)

NOTE: Dimensions have a tolerance of ±1/8″.

NOTE: Electric supply for ALL motors must be within ±10% of nameplate voltage rating (Ex. 230V ±10%= 207 to 253)

Standard Features

• 300 Series Investment Cast Stainless Steel Construction with Viton® seals, Max. Temperature 200° F

• Cast Iron Construction with Buna-N seals, Max. Temperature 180° F

• Dual Volute Design

• Handles 3/8″ Diameter Semi-solids

• Self-cleaning, Clog Resistant Impeller

• Built in Flapper/Check Valve

• Steel Base and Handle

• “Off-the-Shelf” Availability for Many Models

• Nema 56J Motors with Stainless Steel Shafts

• Available in ODP or TEFC, Single or Three Phase

• Self-primes to 20 Ft.